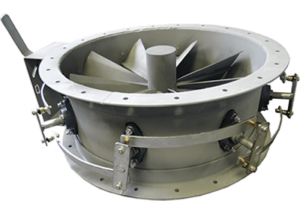

Industrial Dampers

Designed for Precise Airflow Control

Dampers control and/or regulate the flow of air through a ducted system and are integral to the proper operation of processed air.

The majority of our industrial dampers are used in the Automotive Industry, primarily in Paint Finishing applications.

Other industries, such as Appliance, Aerospace. Military, Woodworking and Heat Treatment also use our industrial dampers for their own painting, drying or heating applications.

A major benefit of working with Air Systems for your industrial damper needs is that we have our own fabrication facility so we can design and manufacture dampers and entire systems for your specific application. We are also able to better control quality and lead time given the in-house capabilities we possess.

Industrial Dampers Products

Air Systems is your single source for custom dampers, manual or automatic, for a wide variety of industrial air process applications. The benefits of using Air Systems for your Industrial Damper needs are:

- Custom design with quick delivery

- 20 plus years of application experience in the Industrial market

- Over 90% of orders are designed to customer specifications

- Wide range of configurations, sizes and materials

- Proven quality and reliability with over 10,000 industrial dampers in service

Whether our damper is on a fan inlet/outlet, for fresh air intake of an air house, or the exhaust side of a hot gas or particulate laden air stream, Air Systems has a damper design and the application experience to meet your project needs.