In HVAC systems, air control and distribution play a key role in maintaining comfortable and productive environments. Traditional damper systems have long been the standard for airflow control, but advancements like gear-driven dampers are revolutionizing the landscape. Below we look at the differences between gear-driven dampers and traditional options, exploring their functionality, benefits, and how they impact HVAC performance.

In HVAC systems, air control and distribution play a key role in maintaining comfortable and productive environments. Traditional damper systems have long been the standard for airflow control, but advancements like gear-driven dampers are revolutionizing the landscape. Below we look at the differences between gear-driven dampers and traditional options, exploring their functionality, benefits, and how they impact HVAC performance.

The Role of Dampers in HVAC Systems

Dampers regulate airflow within HVAC system ductwork. They control the volume and flow of air through ducts, allowing for temperature regulation, pressure control, and even ventilation balancing. These devices can be manual or automatic, based on the needs of the system. They are typically used in commercial buildings, industrial settings, and even homes with complex HVAC requirements.

Traditional Damper Designs offer the Conventional Standard

Traditional damper designs rely on a very basic operational mechanism, which has been the reliable standard for decades. While conventional damper designs do offer cost-effective airflow regulation, they can have limitations, particularly in terms of precision and control.

Types of Traditional Dampers

- Butterfly Dampers – Consist of a rotating disc that pivots to allow or block airflow. These are often used for simple open/close control but can be less precise in airflow modulation.

- Opposed Blade Dampers – Feature blades that rotate in opposite directions to evenly regulate airflow. While more effective than butterfly dampers in controlling airflow, they lack the fine-tuned precision offered by more modern systems.

- Parallel Blade Dampers – Similar to opposed blade dampers, but the blades rotate in the same direction. They are best suited for open/closed airflow control but may not offer the same efficiency in reducing noise and actuator torque requirements.

Gear-Driven Dampers Offer an Innovative Approach

Gear-driven dampers bring a new level of precision and control to HVAC systems. These dampers operate through a rack & pinion series of gears that allow for fine adjustments to airflow, resulting in better modulation, efficiency, and overall system performance.

Key Advantages of Gear-Driven Dampers

- Enhanced Precision – Gear-driven mechanisms allow for incremental control of damper blades, enabling more precise airflow adjustments. This leads to more consistent temperatures and better energy efficiency.

- Reduced Wear and Tear – By distributing the mechanical load across a gear system, these dampers tend to experience less mechanical wear than traditional options, and less resistance in the rack & pinion system means less torque required to operate the damper extending their service life.

- Energy Efficiency – Precise control of airflow makes gear-driven dampers ideal for energy-conscious installations. By regulating air distribution more effectively, they can contribute to lower utility costs over time.

- Automated Control Integration – Gear-driven dampers can easily be integrated into modern building automation systems (BAS). This allows for real-time monitoring and automated adjustments, further enhancing energy savings and comfort levels.

Comparison: Gear-Driven Dampers vs. Traditional Dampers

| Feature | Traditional Dampers | Gear-Driven Dampers |

|---|---|---|

| Precision | Moderate | High |

| Durability | Prone to mechanical wear | Reduced wear; longer lifespan |

| Compatibility | Limited to certain systems | Easily integrates with BAS |

| Efficiency | Less efficient airflow control | Higher efficiency with precise control |

| Cost | Typically lower upfront cost | Higher initial cost but long-term savings |

When Are Gear Driven Dampers the Right Choice?

Although gear-driven dampers offer numerous advantages, they may not be necessary for every HVAC installation. For example, with basic residential systems or small scale facilities that have simple airflow control needs, traditional dampers could be a sufficient option. For commercial, industrial, or complex HVAC systems where precision, automation, and efficiency are critical, gear-driven dampers are the superior option.

Upgrading to gear-driven dampers can be a game-changer for HVAC systems, particularly in large-scale or energy-sensitive environments.

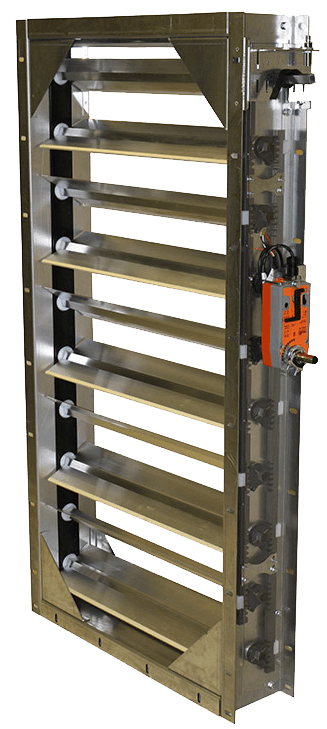

Air Systems Gear Driven Dampers

As experienced specialists in air movement technology, Air Systems developed and patented a gear drive damper design that is cost efficient and offers long term dependability. These gear drive dampers offer unique advantages:

- Highly cost effective

- Ultra-low torque design reduces cost

- Can be used for new or retrofit installations

- “Weldless Design” requires no welding or touch up paint

- Maintenance free

The Air Systems Gear Drive Damper is completely customizable and meets or exceeds typical delivery requirements. Contact us today to learn more.